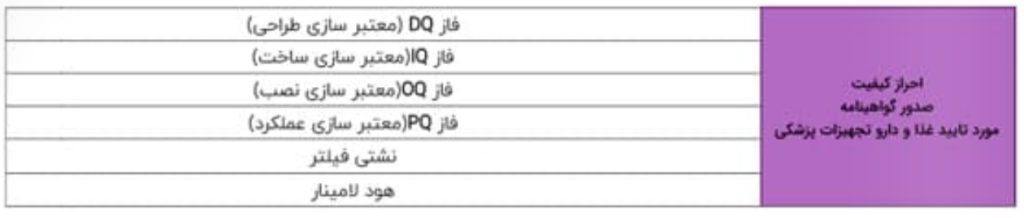

The main services of validation and obtaining approvals

The importance of validation and certification

It is necessary to ensure the installation and operation of the clean room in accordance with ISO 14644. The purpose of building a clean room is to control environmental factors including: temperature, pressure, humidity, sound, vibration and other related process characteristics. For this reason, the clean room It should be inspected after the end of the project and before the start of work to ensure the following:

- The design is suitable for its intended purpose.

- The equipment, facilities and created environment are in harmony with the specifications required by the user.

- Equipment, facilities and working environment are integrated as a system.

- The equipment, facilities and created environment are in accordance with all legal requirements.

Validation process:

(Design Qualification (Dq): a certificate that verifies that the design is suitable for use.

(Installation qualification (IQ): certificate that verifies that the installed components and equipment are in accordance with the design and needs of users.

(operational qualification (OQ): certificate that confirms that the clean room is in ideal conditions during use.

Performance: A certificate that verifies that products and productions are compatible with the environment.

Monitor and Control: Monitoring that all the requirements of ISO 14644 are met during clean room work.

KGS, as the first Acrodite laboratory regarding the ISO 14644 standard, is ready to perform all the above tests and provide valid certificates and test reports approved by Iran's National Certification Organization, National Standards Organization.

Clean room testing and accreditation

After construction and operation, each clean room must be tested and evaluated to determine the correctness of its design and implementation. Among the clean room tests are:

1-Particle counting test

2- Filter leakage test

3- Pressure difference test

4- Air flow pattern test

5-Temperature and relative humidity test

6- Test flow rate and air flow speed

7- Recovery time test

8-Microbial testing and sampling

9-Sound test

10- Lighting test