Design and construction services

Main services: design department

Principles and stages of clean room design and construction:

In the first stage, the number of personnel and people who are present must be specified, the flow diagram of the entry and exit of personnel and materials.

Cleanroom workers are the biggest source of contamination in the cleanroom, so all sensitive processes must be isolated through separate and controllable entrances.

Some pharmaceutical and biological processes are subject to cross-contamination, and in order to prevent cross-contamination, all input and output routes of raw materials and final products must be examined.

In the second step, grade and classify the clean room in terms of cleanliness, choosing the appropriate clean room class according to the type of product and its sterile conditions.

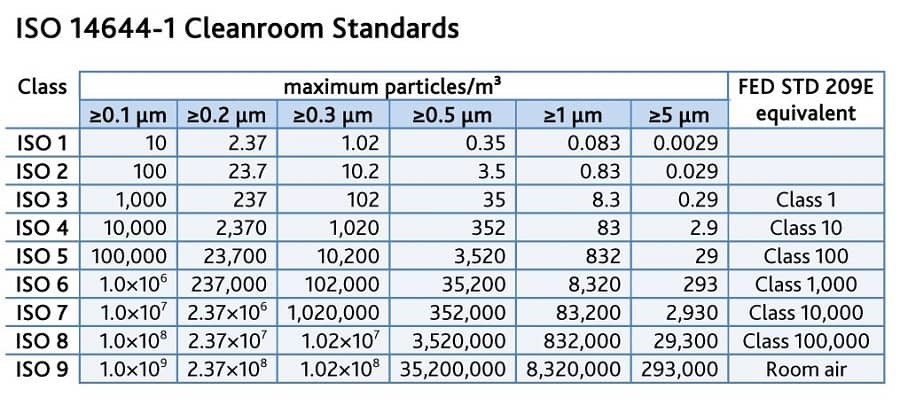

To classify the clean room, one should be familiar with clean room standards such as ISO-14644 and... which are classified based on the number of allowed particles.

In the table below, the number of particles allowed for different classes of clean rooms is specified based on the standard.

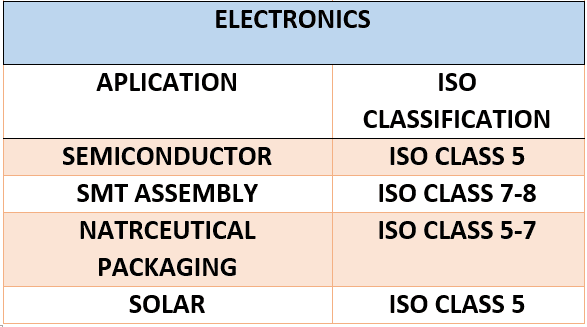

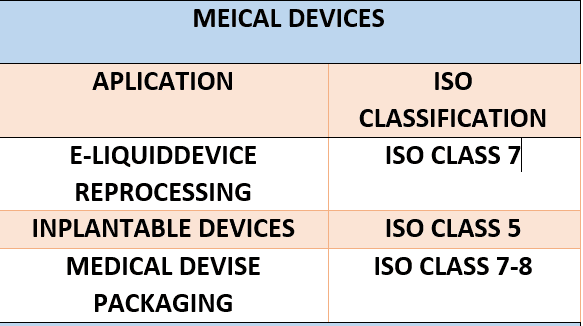

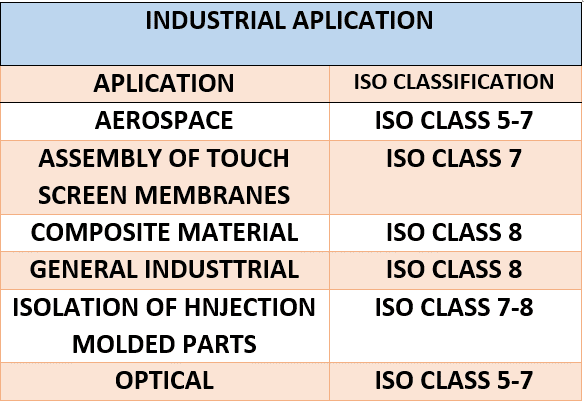

In production processes, the class of clean room should be specified, which is usually determined by relevant organizations such as the Food and Drug Organization or the Medical Equipment Organization.

The table below shows an example of clean room classification and the processes that are carried out in it:

The third stage is the pressure control stage. Clean room pressure difference diagram: PRESSUIZATION

In order to prevent contamination from entering the clean room, there must be a pressure difference between the spaces so that contaminated air does not enter the clean room from the dirty area. This pressure difference is usually considered between 10 and 15 pascals. Pay attention that more pressure difference causes energy loss and it is more difficult to control and it becomes more difficult to open the cleanroom doors.

In the fourth step, the air flow is determined. AIR BALANCE

For clean room balance, all the air entering the clean room (AIR SUPPLY & INFILTRATION) and all the air leaving the clean room (EXHAUST & EXFILTRATION & RETURN) must be equal.

The fifth step is to determine the flow of incoming air from the output filters. The amount of incoming air SUPPLY AIR FLOW

In clean rooms, the amount of incoming air varies according to the production process and use, as well as the class of the clean room.

During the design, according to variables such as: clean room usage - number of personnel - machinery and equipment - clean room class - recovery time RECOVERY TIME..... the amount of incoming air is determined by the designer.

In the table below, the approximate amount of air circulation according to the class of personal clean room

The seventh step is to evaluate other variables.

Other clean room parameters

1_ Temperature: The temperature of the clean room is determined according to variables such as comfort temperature - production process - use of the clean room - machinery, etc., usually the temperature of the clean room is considered between 21 and 24 degrees.

2_ Humidity: The humidity of the clean room depends on factors such as the usage of the clean room and the production process, which usually the relative humidity of the clean room is between 30% and 45%.

3 _ Laminar flow: LAMINAR FLOW

Some sensitive processes must be done under laminar flow and HEPA filter to prevent the transfer of pollution.

4- Electrostatic discharge: some processes are much more than the discharge of electrostatic charge, and when designing the cleanroom, electrostatic flooring and necessary equipment should be considered.

5- Noise and vibration: Some processes are sensitive and sensitive to vibration noise, which should be considered when designing a clean room.

Preparation of a room book for a clean room: ROOM BOOK

In clean rooms, room books must be prepared for all rooms. The clean room book contains information such as the user name, area and height of each room - temperature - humidity - class of the clean room, etc. This information is very accurate and vital and is used in the design of HVAC and mechanical and electrical installations of the clean room.

The eighth step is to summarize the plans designed for the clean room

Map of mechanical facilities

Map of electrical installations

view map

plan map

Clean room interior design

The eighth step:

Mechanical installations and air conditioners, HVAC cleanroom

After performing the above steps and using the obtained information, the mechanical installations and the HVAC system of the clean room are designed. Many variables have an effect on the ventilation system of the clean room, such as the climatic conditions of the region - the amount of the budget - the price of energy - the production needs, etc. Therefore, during the design of the clean room, all factors must be carefully checked and then the thermal and cooling loads of the clean room are calculated. and the data sheet of hygienic air conditioners should be prepared.

Also, in the design of the air conditioning system of the clean room, the following items should be checked and designed:

1- Ventilation channels

2- Air control dampers

3- Air return valves

4- Selection and placement of filters

5- Selection of air conditioner components

6- Choosing the control and monitoring system of the cleanroom ventilation system

The tenth stage is the beginning of the supply of equipment related to the clean room.

The eleventh stage is the beginning of the construction and implementation of the project