Before entering the cleanroom, the changing rooms should be designed and used as an airlock in such a way that the physical isolation of the different stages of changing clothes is provided to minimize the microbial and particle contamination of the protective clothing. .

The area for performing the final step of changing clothes in the clean room changing rooms, in the state of “At rest” should be at the same level as the production environment that leads to it.

The ventilation of the clean room changing rooms should be done effectively by filtered air. The air seals of the clean room should be fed from the independent ventilation system and, if possible, be installed in such a way that the inlet air distribution valve is installed on the side of the cleaner room and the outlet air mesh valve on the side of the less clean room.

The use of separate dressing rooms for entering and leaving clean rooms is desirable in some cases.

In general, facilities for washing hands can be provided only in the area of the first step of changing clothes.

Installation of inlet air distribution valves in the ceiling and discharge/return air mesh valves at a height of approximately 30 cm from the floor and on at least 2 walls.

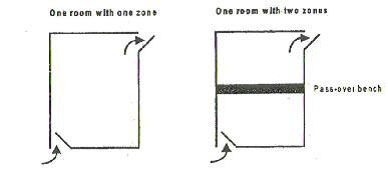

In the design of spaces – clean rooms, containment control techniques such as airlocks play an important role.

A closed space with at least two doors between two spaces with different cleanliness classes, in order to control the air flow between the rooms when entering and leaving.

Types of air seals:

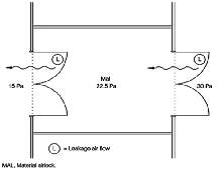

− Cascade airlock

− Sink airlock

− Bubble airlock

Attention: The doors should return to the space with more pressure.

Cascade airlock High pressure on one side of the air seal and low pressure on the opposite side.

Sink airlock Low pressure inside the air seal and high pressure on both sides

Bubble airlock High pressure inside the air seal and low pressure on both sides.

بدون دیدگاه